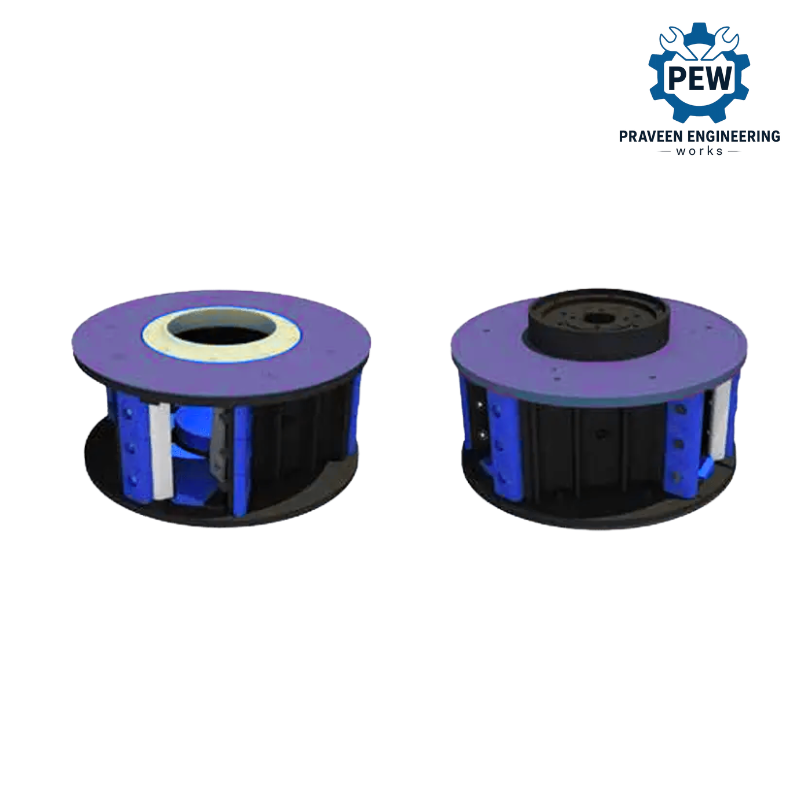

What is a VSI Crusher?

A VSI (Vertical Shaft Impactor) crusher is a high-speed machine widely used in stone crushing, mining, and construction. It crushes rock, gravel, and minerals into fine particles using high-velocity impact energy and there are different Crusher Spare parts for different model .

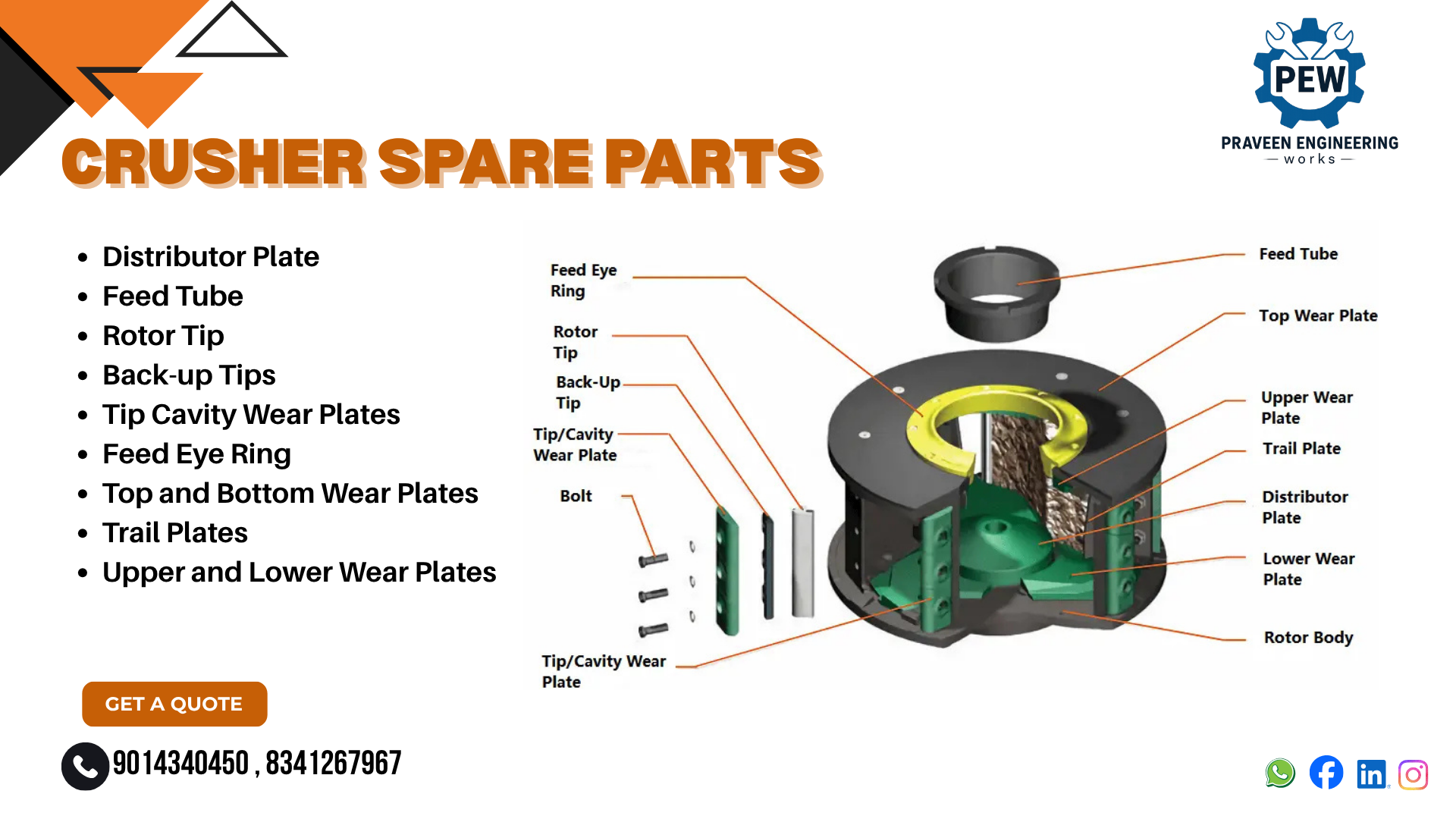

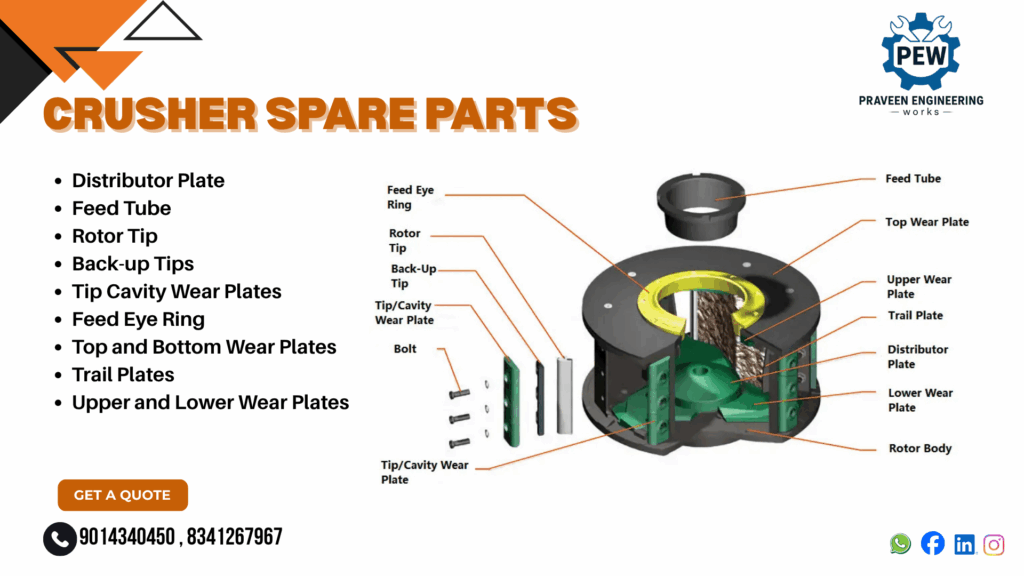

The main components include a rotor, crushing chamber, and discharge port — all built with wear-resistant materials to ensure long-term performance.

Here are the key parts of a VSI crusher and their functions:

- Distributor Plate

- Rotor Tips

- Upper and Lower Wear Plates

- Back-up Tips

- Tip / Cavity Wear Plates

- Trail Plates

- Feed Tube

- Feed Eye Ring

- Top and Bottom Wear Plates

⚙️ VSI Crusher Parts and Their Functions

At Praveen Engineering Works, we supply premium VSI Crusher Parts that enhance machine efficiency and durability. Below are the main components and their functions:

🔹 Distributor Plate

Located above the rotor, the Distributor Plate evenly distributes feed material into the crushing chamber. It endures maximum impact wear and typically requires the most frequent replacement.

🔹 Feed Tube

All feed material passes through the Feed Tube, making it prone to abrasive wear. It’s secured into the spider assembly using a clamp plate and spring handle for easy replacement.

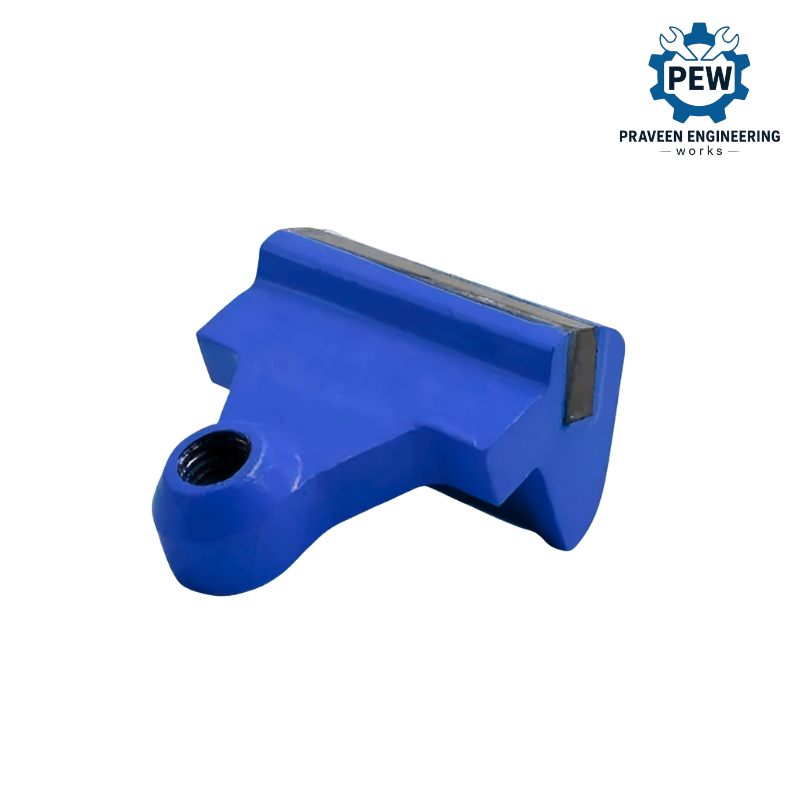

🔹 Rotor Tips

The Rotor Tips are the last parts to contact feed material before discharge. They often include Tungsten carbide inserts for longer wear life. These are critical for maintaining crushing efficiency.

🔹 Back-Up Tips

Back-Up Tips protect the rotor when a primary tip wears out or breaks. They prevent direct rotor damage and help reduce downtime.

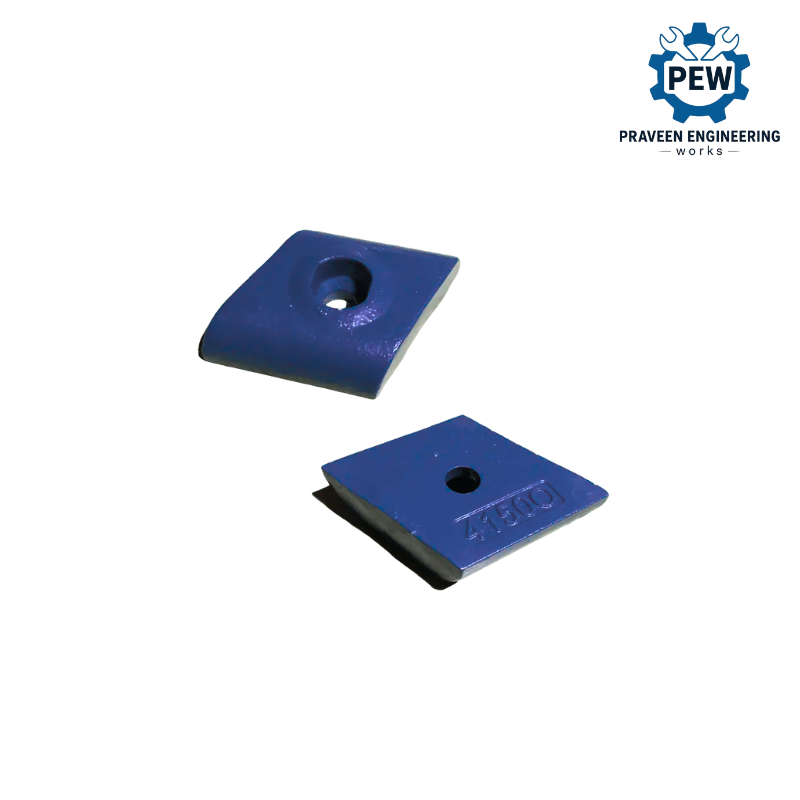

🔹 Tip / Cavity Wear Plates

These plates shield the rotor edges from rebounding particles in the chamber, ensuring longer life and stable performance during operation.

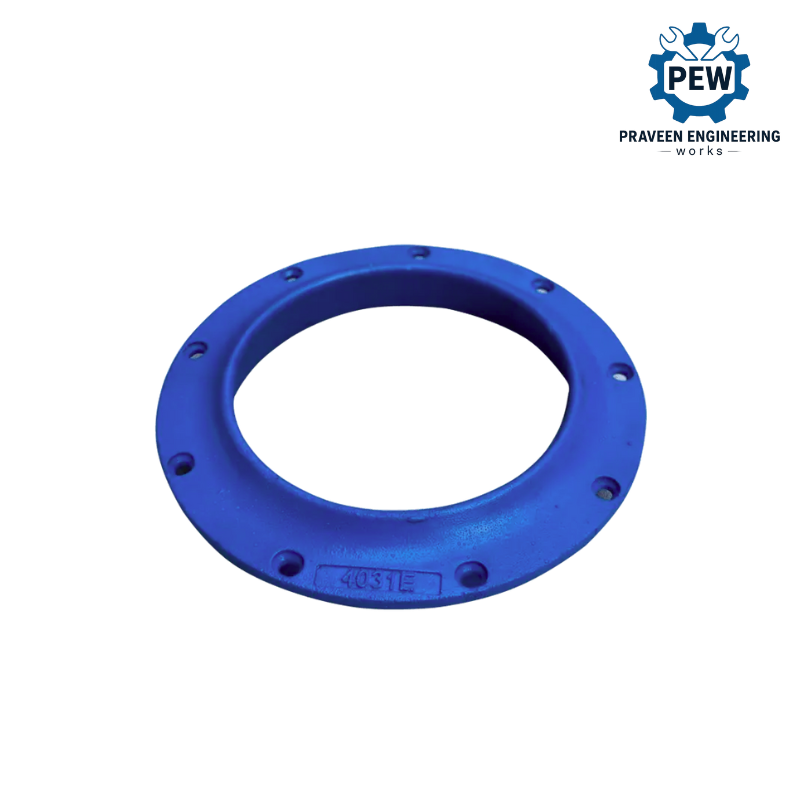

🔹 Feed Eye Ring

The Feed Eye Ring experiences minimal wear under normal conditions and can often be rotated multiple times to extend lifespan.

🔹 Top and Bottom Wear Plates

Designed to protect the outer rotor surfaces, these plates prevent damage from excess material buildup and ensure smooth flow during operation.

🔹 Trail Plates

Trail Plates retain material buildup inside the rotor behind the tips, playing a key role in maintaining balanced rotor performance.

🔹 Upper and Lower Wear Plates

These protect the inner rotor surfaces from direct material impact, reducing wear and maintaining smooth feed flow.

💡 Why Choose Praveen Engineering Works?

At Praveen Engineering Works, we specialize in manufacturing and supplying high-quality VSI Crusher Spare Parts including rotor tips, wear plates, distributor plates, and feed tubes.

✅ Precision-engineered parts

✅ High wear resistance

✅ Competitive pricing

✅ Trusted by quarry and mining industries

📞 Get in Touch

Looking for reliable VSI Crusher Parts or Stone Crusher Components?

👉 Request a Quote today or Contact Us for more product details.